DAF

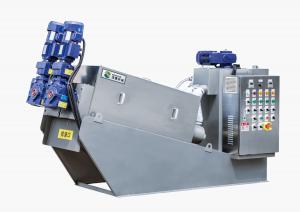

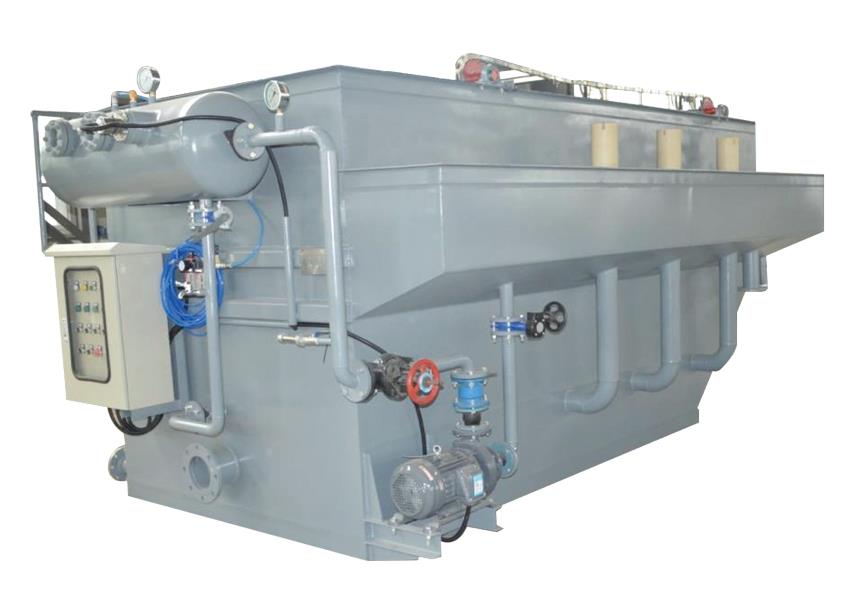

ConsultationProduct overview: As a kind of solid-liquid separation equipment commonly used in sewage treatment industry, the horizontal flow dissolved air floatation machine can effectively remove the suspended solids, grease and rubber in sewage, and it is the main equipment for sewage preliminary treatment.

Product features: It can effectively remove the light flocs which are difficult to precipitate in wastewater. Large processing capacity, high efficiency, less land occupation and wide range of use. It is widely used in petroleum, chemical industry, printing and dyeing, papermaking, oil refining, leather, steel, mechanical processing, starch, food and other sewage treatment.

PRODUCT INTRODUCTION

PRODUCT INTRODUCTION

As a kind of solid-liquid separation equipment commonly used in sewage treatment industry, the horizontal flow dissolved air floatation machine can effectively remove the suspended solids, grease and rubber in sewage, and it is the main equipment for sewage preliminary treatment. It is widely used in petroleum, chemical industry, printing and dyeing, papermaking, oil refining, leather, steel, mechanical processing, starch, food and other sewage treatment.

Feature

◆The fine microbubbles produced can achieve good air flotation effect.

◆In the process of production and operation, the amount of flocculant used is very small, and the total gas cost is also very low

◆It is very easy to control the whole water quality and quantity by strictly controlling the equipment operation through the control system.

Working principle

The air dissolving tank generates the air dissolving water, and the air dissolving water is released to the water to be treated by decompressing through the releaser. The air dissolved in the water is released from the water to form 20-40um micro bubbles. The micro bubbles combine with the suspended solids in the sewage to make the proportion of the suspended solids smaller than the water, and gradually float to the water surface to form scum. There is a scraper system on the water surface to scrape the scum into the sludge tank. Clear water enters the clean water tank through the overflow tank at the lower part.

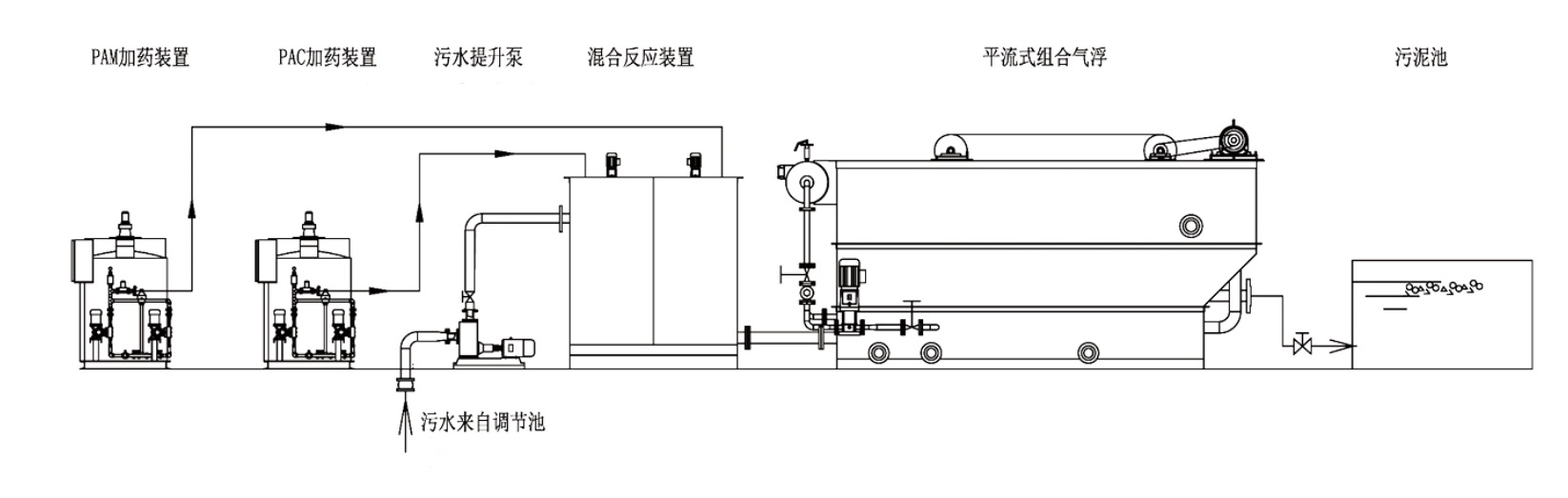

Process flow

| Model | Capacity(m3/h) | Reflux(%) | Motor power(KW) | Scraper power(KW) | Air compressor power(KW) | Dissolved air tank(mm) | Dimension (mm) |

| MPQF-5 | 4-5 | 35 | 3 | 0.37 | 1.5 | ?400*1000 | 3300*1800*220 |

| MPQF-10 | 8-10 | 35 | 3 | 0.37 | 1.5 | ?500*1512 | 4000,2100*2200 |

| MPQF-15 | 10-15 | 35 | 3 | 0.37 | 1.5 | ?500*1512 | 4400*2100*2200 |

| MPQF-20 | 15-20 | 35 | 7.5 | 0.37 | 1.5 | ?500*1512 | 4600*2400*2200 |

| MPQF-30 | 20-30 | 35 | 7.5 | 0.37 | 1.5 | ?500*1512 | 5200*2600*2400 |

| MPQF-40 | 30-40 | 35 | 7.5 | 0.55 | 1.5 | ?600*1880 | 6000*2600*2400 |

| MPQF-50 | 40-50 | 35 | 7.5 | 0.55 | 1.5 | ?600*1880 | 7000,2600*2400 |

| MPQF-60 | 50-60 | 35 | 7.5 | 0.55 | 1.5 | ?600*1880 | 7600*2800,2400 |

| MPQF-70 | 60-70 | 35 | 7.5 | 0.55 | 1.5 | ?650*2034 | 8400*2800*2400 |

| MPQF-80 | 70-80 | 35 | 7.5 | 0.55 | 1.5 | ?650*2034 | 9200*2800*2400 |

| MPQF-100 | 90-100 | 35 | 15 | 0.55 | 3 | ?700*1980 | 10000*2800*2600 |

| MPQF-150 | 125-150 | 40 | 22 | 1.1 | 3 | ?700*1980 | 13500-2800*2600 |

| MPQF-200 | 175-200 | 40 | 22 | 1.1 | 3 | ?800*2100 | 15800*2800*2600 |

| MPQF-300 | 250-300 | 40 | 37 | 1.1 | 5.5 | ?1000*2900 | 19200*3400*2800 |

- Last article: no more;

- Next article: Truss Type Sludge Classifier